出版物

Precitec is partner at the European LASERWAY project

The LaserWay project aims to revolutionize the manufacturing industry by replacing conventional, inefficient, and environmentally harmful methods with…

Cailabs and Precitec shape e-mobility with advanced laser technology

The cornerstone of the collaboration between Cailabs and Precitec is the integration of Cailabs’ advanced beam shaping modules into Precitec’s…

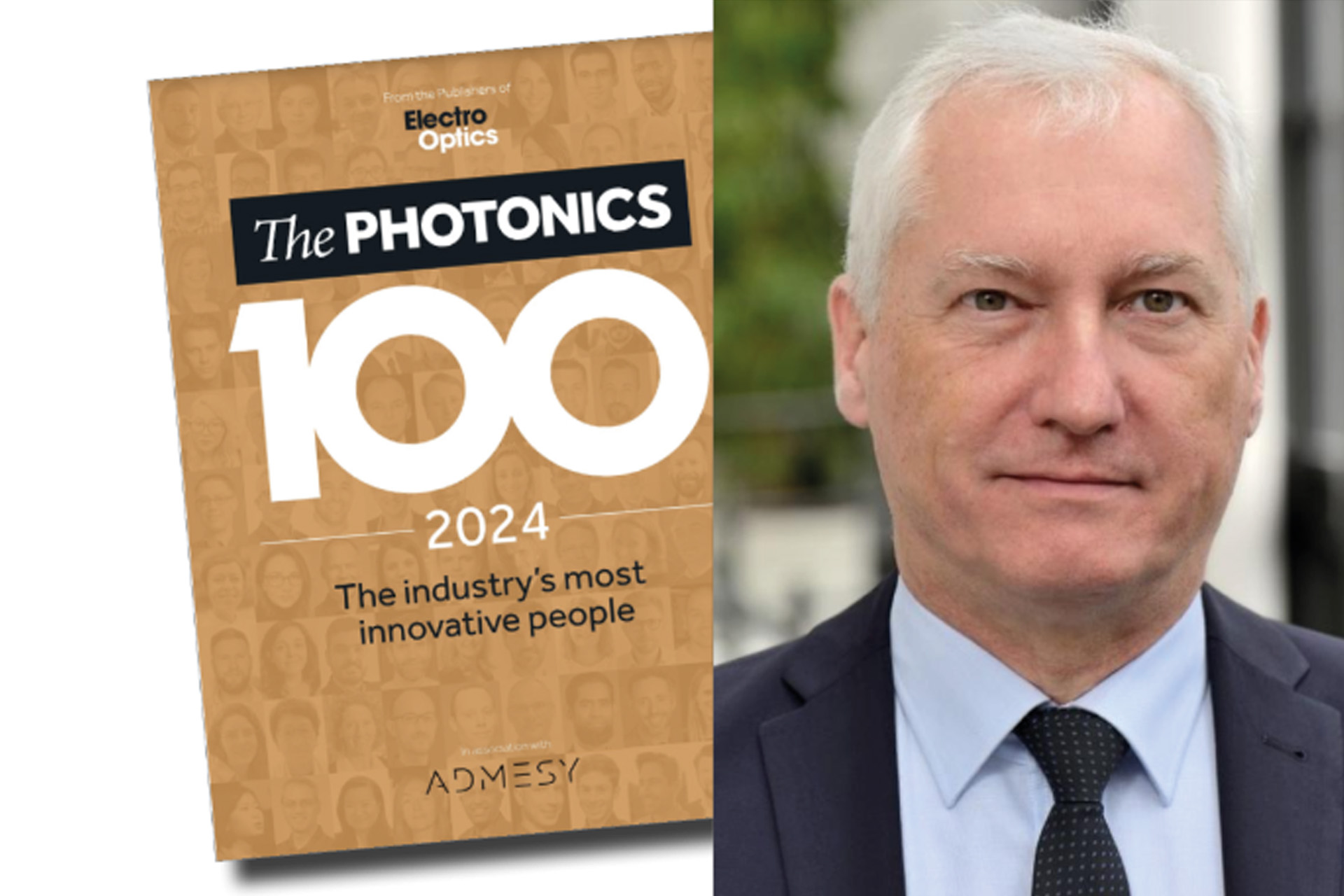

Dr. Markus Kogel-Hollacher is presenting a paper at this year´s Photonics West

Precitec Optronik Head of R&D and Photonics 100 honouree Dr. Markus Kogel-Hollacher is presenting a paper at this year's Photonics West.

He talked…

![[Translate to Japanisch:] Dr. Markus Kogel-Hollacher speaks about Artificial Intelligence in laser processing and process monitoring](/fileadmin/News/news-images/lasertechnology/Markus_Kogel_Hollacher.jpg)

これまで見えなかったものがAIによって見えるようになる

PHOTONICS のインタビューで、Markus Kogel-Hollacher 氏は、Precitec が具体的な顧客利益を生み出すために AI (人工知能) をどのように活用しているか、アルゴリズムのトレーニングが困難だがやりがいのある仕事である理由、そして AI…

e-モビリティの開発においてレーザープロセスがこれほど重要な役割を果たすのはなぜですか?

フォトニクス、特にレーザーとセンサーは、今後数年間でバッテリー市場で重要な役割を果たす態勢が整っています。電気自動車のバッテリー製造の進化には、従来の工場からギガファクトリーの設立への移行が必要です。この成長産業にとってレーザープロセスが重要な役割を果たす理由をこの記事で読んでください。

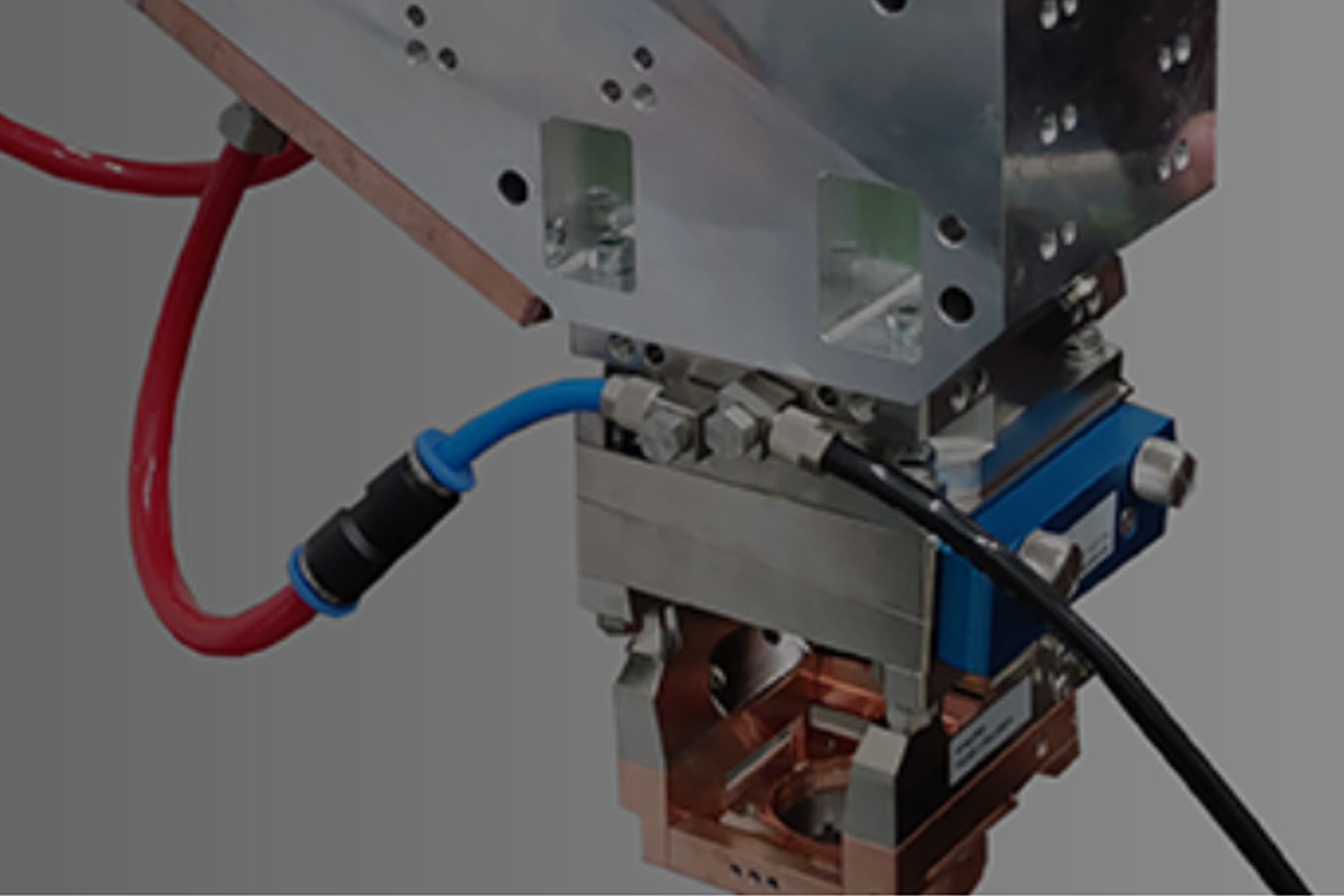

Laser welding monitoring in the field of e-mobility

As the global automotive industry is stepping into the future with e-mobility, the main challenge has become mass-production of batteries. High-speed…

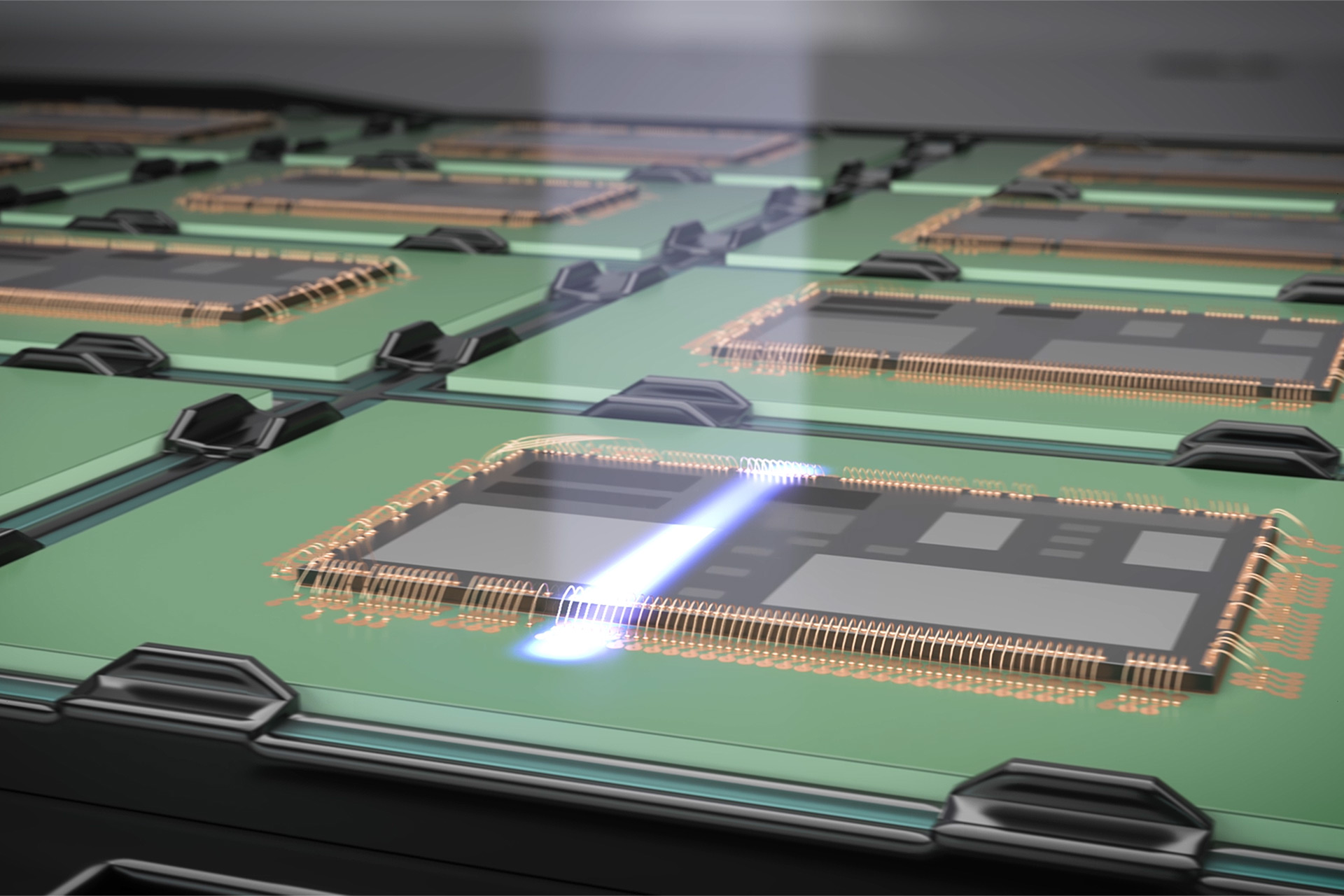

Challenges Wire Bond Inspection

The article from Semi Engineering explores challenges in the wire bonding industry as seen by key players in the markets. Interesting insights and…

And the Prism Award 2023 goes to..

Precitec 3D Metrology wins prestigious Prism Award 2023.

SPIE, the international society for optics and photonics, honored the Flying Spot Scanner…

![[Translate to Japanisch:] Enovasense sensor at work](/fileadmin/News/Enovasense_Sensor_1920x1280.jpg)

Precitec Acquires Majority Stake in Enovasense Thickness Sensor Company

Precitec Optronik has acquired a majority stake in the French start-up Enovasense with its technology to measure the thickness of all kinds of…

![[Translate to Japanisch:] Laser welding systems help to more innovation](/fileadmin/News/Laser_Welding_solutions_for_Emobility_1920x1280.jpg)

Precitec Sees a Bright Future in Laser Welding Systems

"At Precitec, innovation is key" so Klaus Loeffler, Managing Director & Chief Sales Officer at Precitec. To widen the technology, promoting such…