Publications

Precitec is partner at the European LASERWAY project

The LaserWay project aims to revolutionize the manufacturing industry by replacing conventional, inefficient, and environmentally harmful methods with…

Cailabs and Precitec shape e-mobility with advanced laser technology

The cornerstone of the collaboration between Cailabs and Precitec is the integration of Cailabs’ advanced beam shaping modules into Precitec’s…

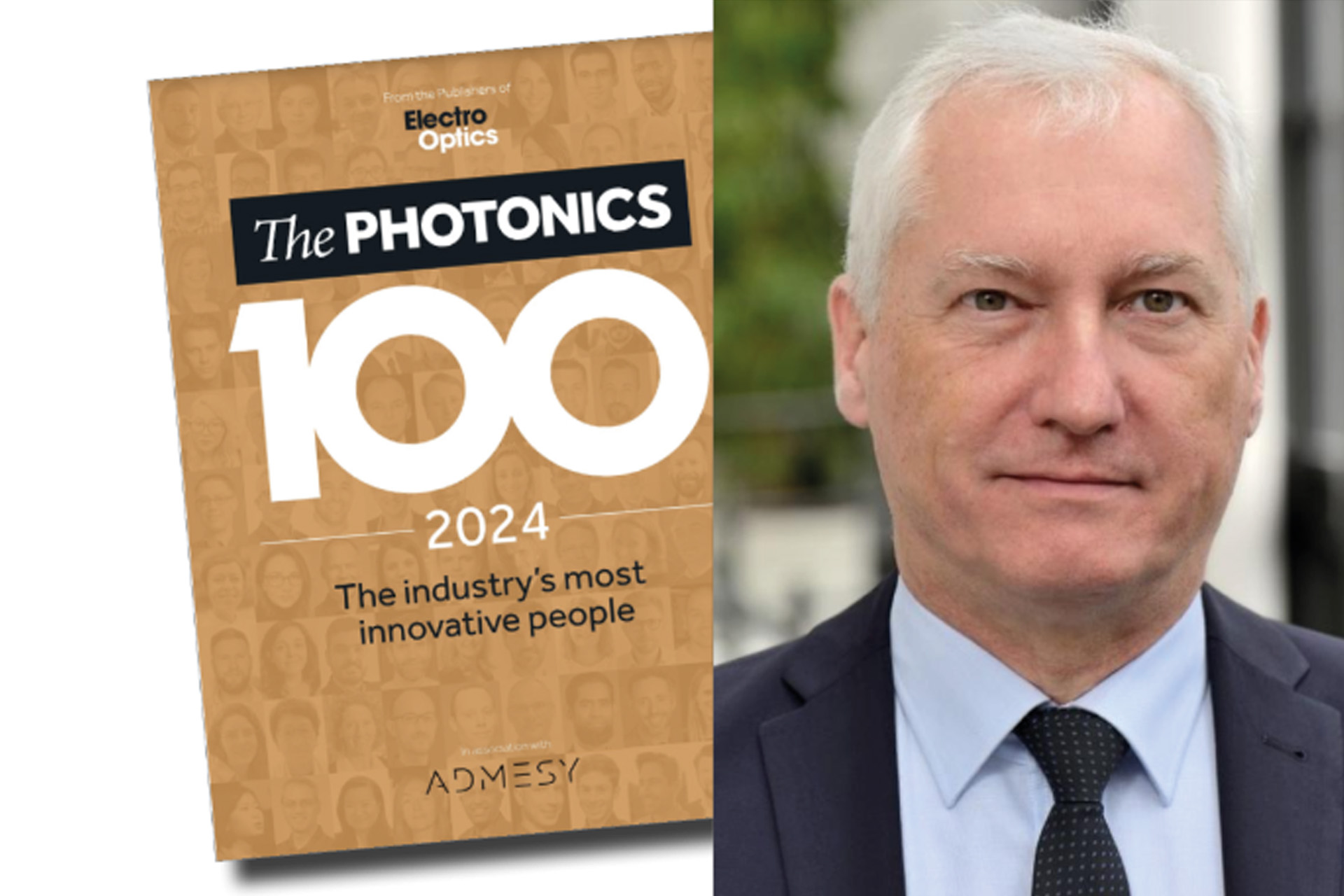

Dr. Markus Kogel-Hollacher is presenting a paper at this year´s Photonics West

Precitec Optronik Head of R&D and Photonics 100 honouree Dr. Markus Kogel-Hollacher is presenting a paper at this year's Photonics West.

He talked…

![[Translate to Französisch:] Dr. Markus Kogel-Hollacher speaks about Artificial Intelligence in laser processing and process monitoring](/fileadmin/News/news-images/lasertechnology/Markus_Kogel_Hollacher.jpg)

Ce qui était auparavant invisible devient visible grâce à l’IA

Dans l'interview PHOTONICS, Markus Kogel-Hollacher explique comment Precitec utilise l'IA (intelligence artificielle) pour créer un bénéfice client…

Pourquoi les procédés laser jouent-ils un rôle si essentiel dans le développement de la mobilité électrique ?

La photonique, en particulier les lasers et les capteurs, est sur le point de jouer un rôle important sur le marché des batteries dans les années à…

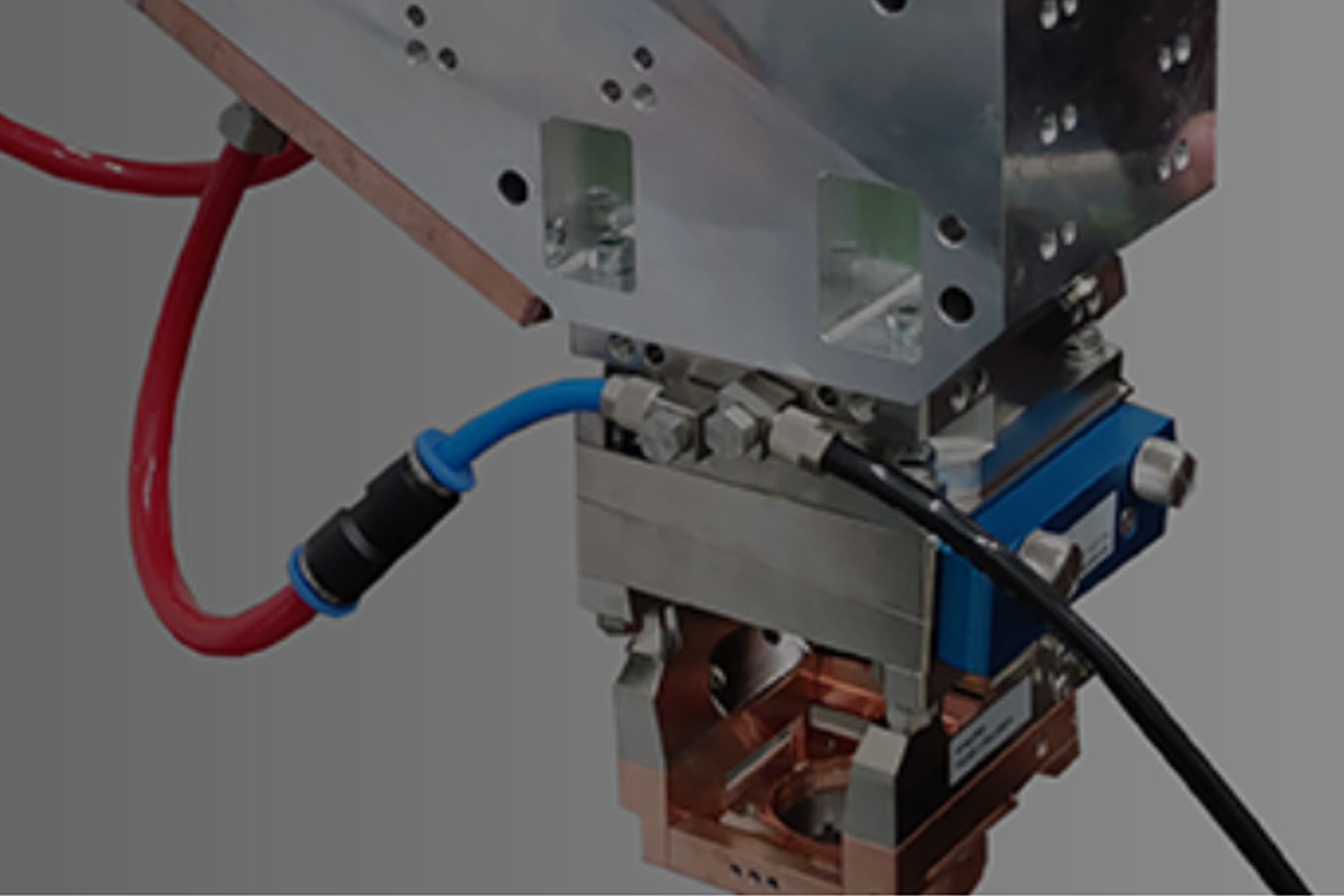

Laser welding monitoring in the field of e-mobility

As the global automotive industry is stepping into the future with e-mobility, the main challenge has become mass-production of batteries. High-speed…

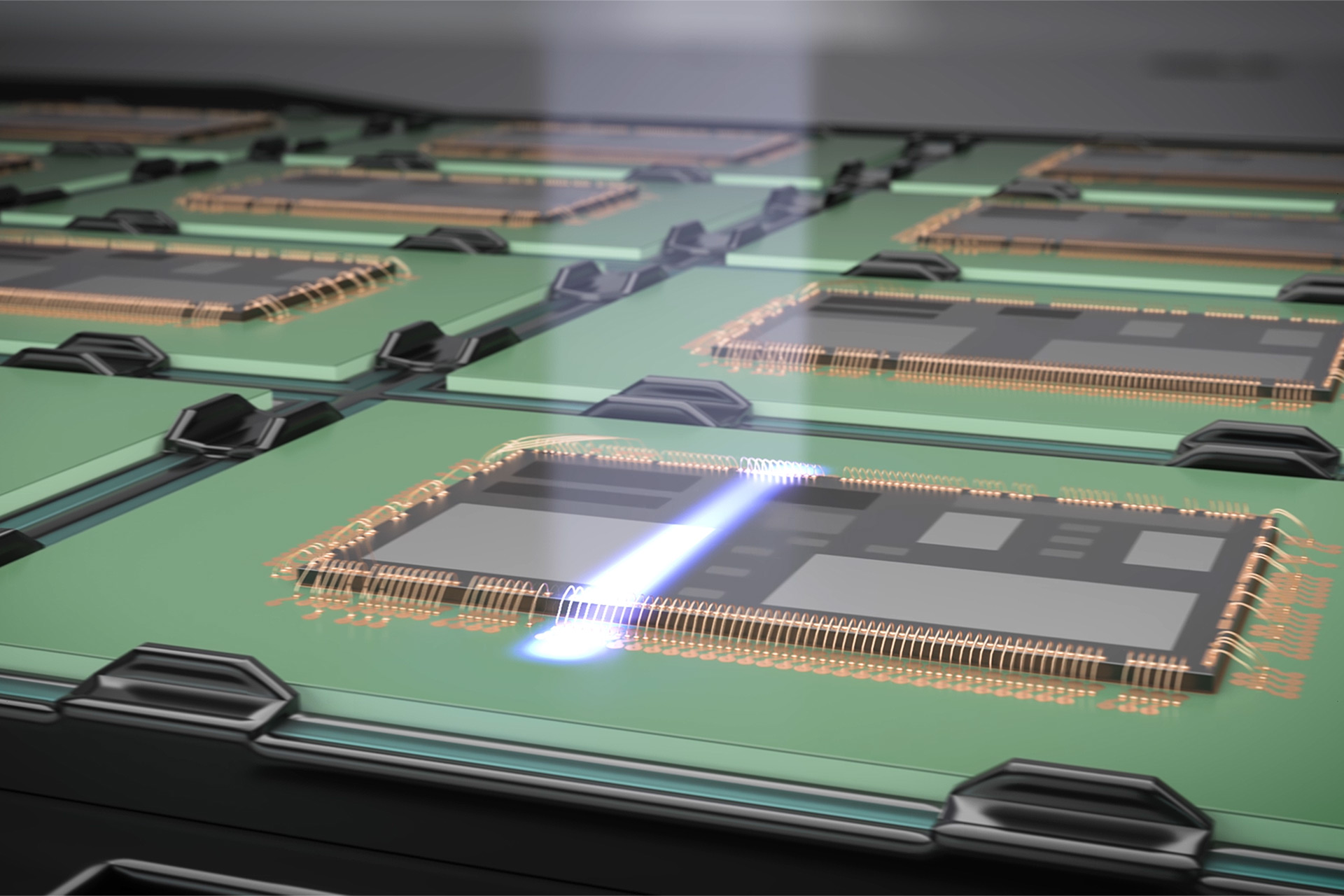

Challenges Wire Bond Inspection

The article from Semi Engineering explores challenges in the wire bonding industry as seen by key players in the markets. Interesting insights and…

And the Prism Award 2023 goes to..

Precitec 3D Metrology wins prestigious Prism Award 2023.

SPIE, the international society for optics and photonics, honored the Flying Spot Scanner…

![[Translate to Französisch:] Enovasense sensor at work](/fileadmin/News/Enovasense_Sensor_1920x1280.jpg)

Precitec acquiert une participation majoritaire dans la société Enovasense

Precitec a acquis une participation majoritaire dans la start-up française Enovasense dont la technologie permet de mesurer l'épaisseur de tous types…

![[Translate to Französisch:] Les systèmes de soudage laser sont très innovants](/fileadmin/News/Laser_Welding_solutions_for_Emobility_1920x1280.jpg)

Precitec voit un bel avenir pour les systèmes de soudage au laser

"Chez Precitec, l'innovation est la clé" déclare Klaus Loeffler, directeur général et directeur des ventes chez Precitec. Pour élargir la technologie,…